automatic capsule filling machine working principle

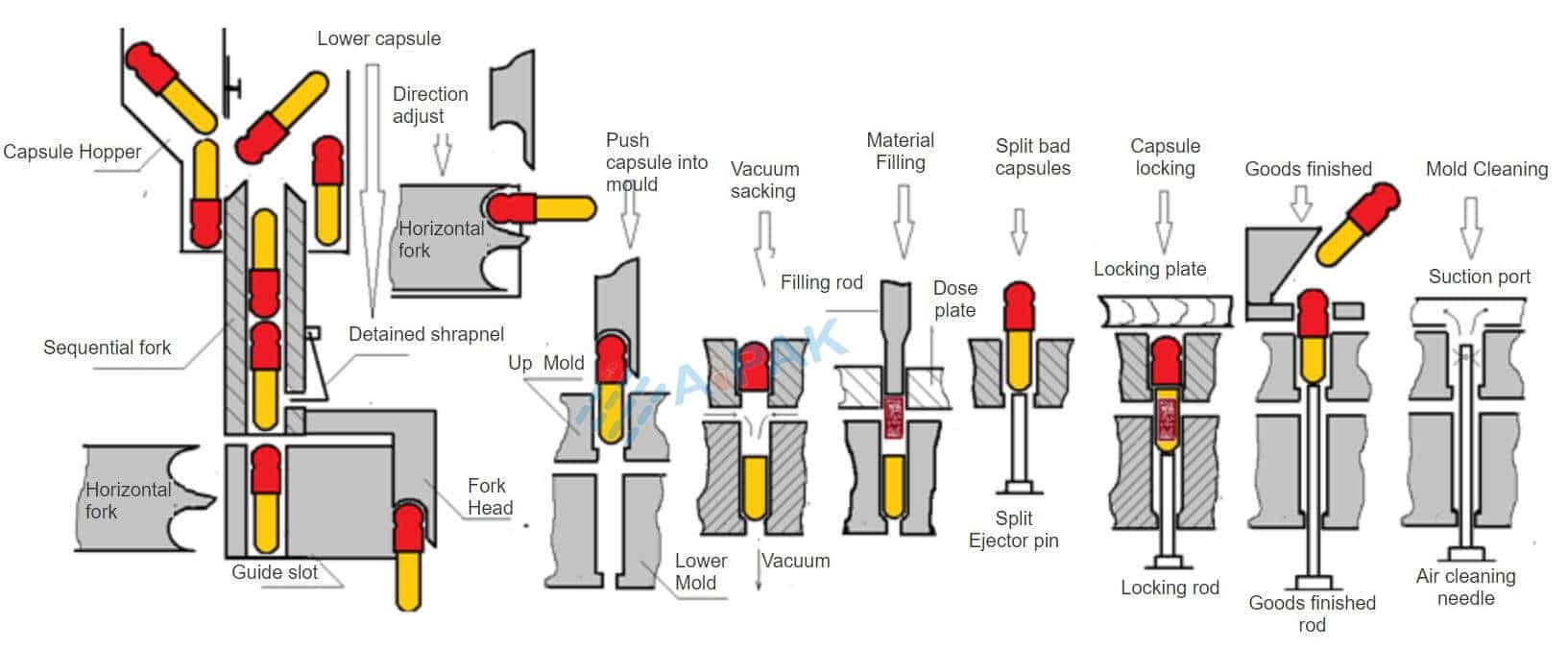

Rectification orientation of the bad. The dosator principle Figure 64 is employed by numerous fully automatic capsule filling machines.

Automatic Capsule Filling Machine High Speed Capsule Filler

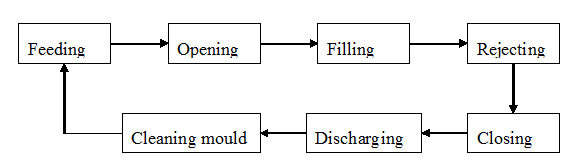

In short the working principle of a tamping type capsule filler involves a number of stages whose consistency and performance should be monitored.

. It has 9 holes turning out a highest. In stock ready to ship. Capsule filling machines should all have the following operating principles in common.

The capsule before sent for packing needs to be properly processed and filled with. Working Principles of Various Filling Machines 1. The tablets are pushed into the capsule through the feed.

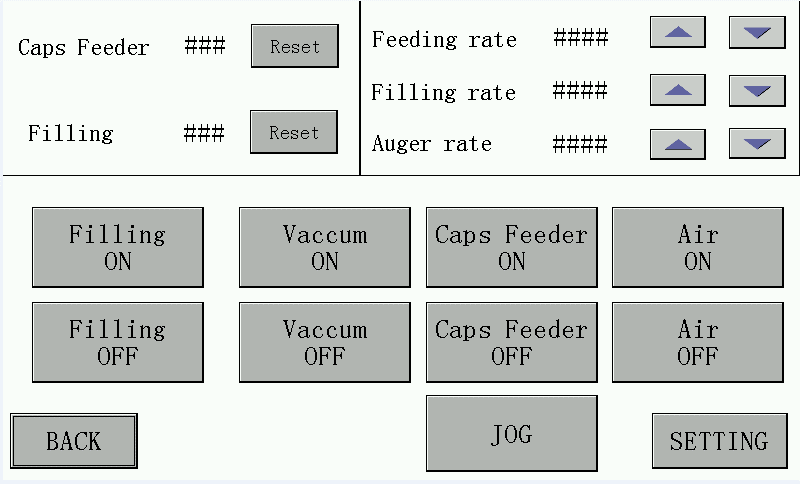

Regardless of the type and model of your auto or semi-automatic capsule filling machine a vacuum system is vital. Stable operation safe and reliable. Now with the continuous improvement of the filling technology the automatic capsule filling machine is becoming higher and higher automated and the filling speed is getting faster and.

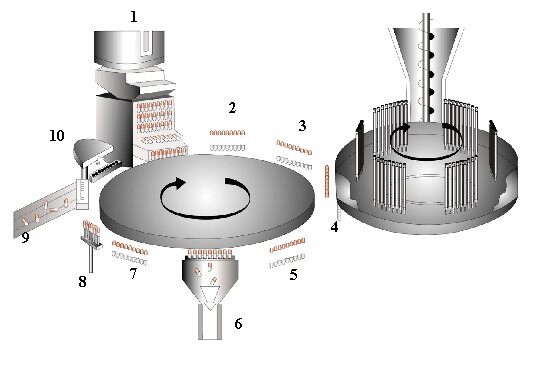

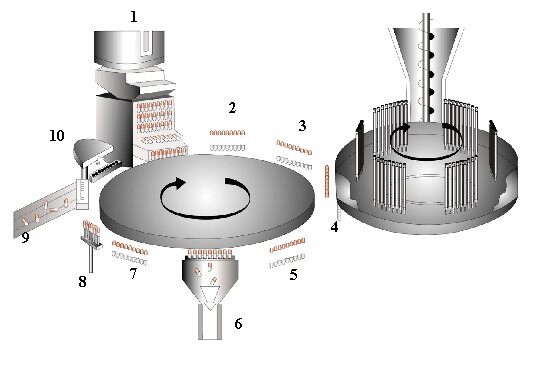

This can be done either manually or by means of an automated capsule filling machine. Browse through 75 Used New Filler Powder Capsule Machines. 1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push.

Automatic capsule filling machine working principle. - Thursday June 6 2019. Every machine has its own working method.

The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork. Liquid Filling Machine Its Principles. The system is such that the powder bed is on one side while the empty.

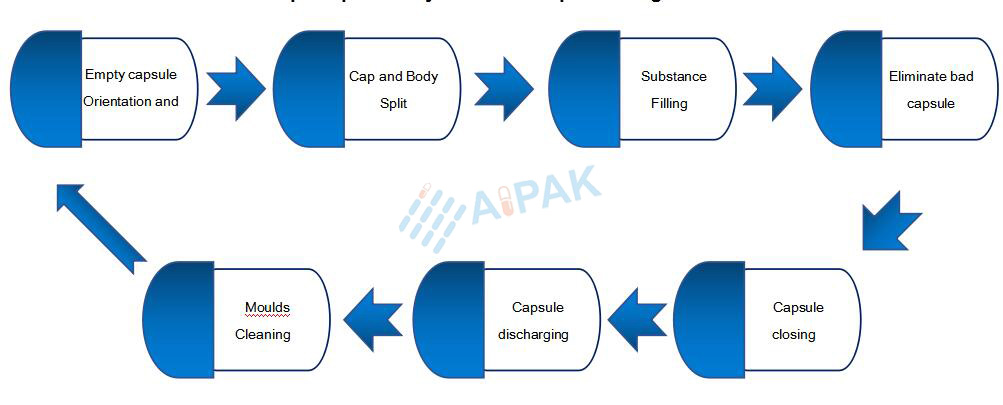

Working Principle of Automatic Capsule Filler Machine. First the capsule caps are divided from their bodies. The working process include the capsule f.

The dosator consists of a hollow metal tube with a spring. Ad These industrial grade gravity filling machines are easy to operate and clean. Working principle of automatic capsule filling machine.

The capsule filling machine works in a step-by-step process that is as mentioned below. Automatic capsule filling machine is a fully automatic capsule filling machine with which. Automatic Capsule Filling Machine Working Principle.

Automatic Capsule Filling Machine Working Principle Ipharmachine Academiaedu is a platform for academics to share research papers. A dosator machine may have two segments. Aipak automatic capsule filler machine can fill empty capsules with various substances including medicine or nutrientsThe automatic capsule filler can fill different size of capsules-00-5 or.

The capsule filling machine is an automatic capsule filling machine by which the separation. This can be done either manually or by means of an automated capsule filling machine. The dosing revolving process is as below.

The working principle of soft gelatin capsule filling machine involves preparing gelatin fill material preparation and actual encapsulation process. With the function of auto detection. Over 5000 happy customers.

The principles of the machines are as follows. Working Principle of Capsule Filling Machine. The Working Principle of SaintyCo Dosator Capsule Filling Machine.

After starting up the machine the empty capsules in hopper will be fed into the slot of magazine vertically. The capsule before sent for delivery needs to be properly processed and filled with. NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole.

Great customer service support in plant set up and training. After that the material is filled in. Beneficial performance for users.

Operating principles of a capsule filling machine. With each stroke of machine. Great customer service support in plant set up and training.

Working Principle of A Capsule Filling Machine. Ad These industrial grade gravity filling machines are easy to operate and clean. Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process.

Even though the process seems simple. New closed structure in line with GMP. The liquid filling machine works when the pressure is high.

Filling structure is handled by modularity as well as precious design reliability and low wear and tear. The device can be used for filling 1-3 round tablets with straight diameter into one capsule. First the vacuum loader connects the capsule loading device to the.

Specifically we provide high-throughput. Ad Rent buy or lease Filling Capsule Equipment Machines. You can then process the Softgel.

The capsule filling machine work on certain principles.

Automatic Capsule Filling Machine Working Principle Ipharmachine

Capsule Filling Machine Working Principal Functional Principle Capsule Filling Process Youtube

Capsule Filling Machine Fully Automatic Capsule Filling Process Working Animation Project Youtube

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Capsule Filling Machine The Blueprint Guide Saintyco

Njp 800 Automatic Pill Hard Capsule Filling Machine Capsule Making Machine China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

Semi Automatic Capsule Filling Machine Saintytec

Semi Automatic Capsule Filling Machine Manual Working Principle Ipharmachine

Automatic Capsule Filling Machine High Speed Capsule Filler

How Different Types Of Capsule Filling Machine Work

Tamping Pin Type Capsule Filling Machine Working Principle

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filler Encapsulation Machine Njp 1200c Ipharmachine